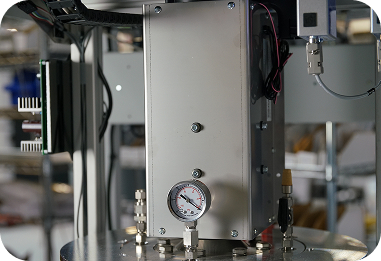

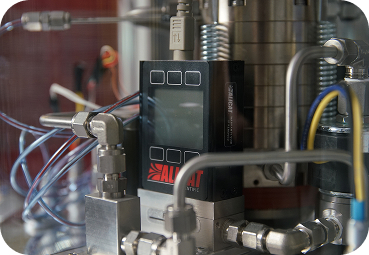

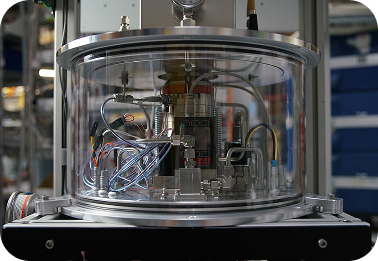

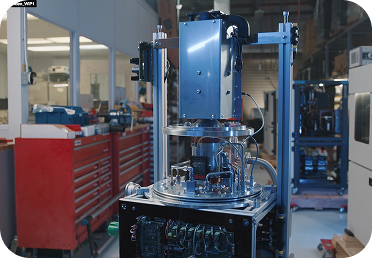

The G3 Frost Point Generator

Powerful Flexibility

Smart Insulation & Independently Controlled Outputs

The G3 offers up to three independent flow controlled outputs. Each output can flow up to 5 liters/minute, with a total combined flow up to 10 liters/minute.Specifications

Operation

Documents

Warranty

Accessories

Specifications

Specifications

The G3’s specifications are outlined, below

| Generated Humidity Output: | |

|---|---|

| Water Vapor Concentration Range | <1 PPB … 12000 PPM |

| Frost/Dew Point Temperature Range | -120 °C FP … +10 °C DP |

| Frost/Dew Point Temperature Stability | ±0.05 °C |

| Frost/Dew Point Temperature Accuracy | ±0.1 °C (FP >-80 °C) |

| Generated Flow Rate Output: | |

| Gas Flow Rate Range, per output | 1 to 3 outputs at 0 … 5 slpm each |

| Gas Flow Rate Range, total | 0 … 10 slpm |

| Gas Flow Rate Accuracy | ±0.2 slpm |

| Gas Flow Rate Stability | ±0.1 slpm |

| Temperature: | |

| Saturation Temperature Control Range | -120 °C … +20 °C |

| Saturation Temperature Control Accuracy | ±0.05 °C |

| Saturation Temperature Control Stability | ±0.03 °C |

| Test Temperature Connections | 2 external temperature connections |

| Measurement Accuracy | ±0.05 °C |

| Probe Type | Pt100, 4-wire |

| Pressure: | |

| Saturation Pressure Control Range | Near ambient to 1 MPa (150 psia) |

| Saturation Pressure Accuracy | ±0.05% FS |

| Test Pressure Measurement Range | 0.07 … 0.12 MPa (11 … 17 psia) |

| Test Temperature Connections | 2 external temperature connections |

| Test Pressure Accuracy | ±0.05% FS |

| Utility Requirements: | |

| Gas supply | 0.3 … 1MPa @ 10 slpm. Max pressure 3 MPa |

| Gas Type | Dry air or nitrogen |

| Supply Voltage | 100-240 VAC, 50/60 Hz, Single phase |

| Power Consumption | 1.5kW |

| Environmental: | |

| Operating temperature | +15 °C … +40 °C |

| Storage temperature | 0 °C … +50 °C |

| Humidity | 10 … 95 %RH, non-condensing |

| Weight and Dimensions: | |

| Height | 1.2m |

| Width | 0.8m |

| Depth | 0.8m |

| Shipping Weight | 318 kg |

Operation

Operation

The G3 is composed of multiple components and has specific facility requirements. Please read the entire G3 manual before operating.

Documents

Warranty

Warranty

RH Systems (RHS) warrants the products it manufactures or distributes to be free of defects in material and workmanship under normal use and service when operated within the specified design limitations for a period of 12 months from date of initial shipment. Under this Warranty, RHS will, at its discretion, repair or replace any component that upon examination by RHS or its duly authorized representatives proves to be defective during the warranty period provided the system is returned to the factory for inspection and repair shipping prepaid. Improper or unauthorized maintenance, storage, repair, or alteration of any kind by personnel other than RHS or its duly authorized representatives may void all warranties. Warranty may also be voided for misuse, neglect, accident, corrosion, and improper installation. This Warranty is exclusive and in lieu of any and all other warranties of merchantability, fitness for a particular purpose, or any other warranty, expressed or implied, and all other liabilities and obligations on the part of RHS. RHS will not be liable for any other claims or damages, either direct, indirect, or consequential arising out of the use of its products.

Accessories

Accessories

Let’s Chat

At RH Systems, we’re constantly pushing ourselves towards advancing our products and services for a wide range of clients, setting a new standard for accuracy and paving the way for future breakthroughs.

Customer satisfaction is the foundation of our reputation, so we never take a one-size-fits-all approach. We work with you to understand your needs and provide customized solutions that work seamlessly right from the jump.

Ready to chat with our Sales Team? Send an email to sales@rhs.com and we’ll get right back to you.

Let’s Connect

Frequently Asked Questions

9am – 5pm Arizona Time

1225 West Houston Ave, Gilbert, AZ 85233

As a NVLAP accredited laboratory, RH Systems is reassessed to ensure that our quality and practices maintain such standards (NVLAP Laboratory Code 600161-0). The National Institute of Standards and Technology (NIST) administers the National Voluntary Laboratory Accreditation Program (NVLAP), which accredits public and private laboratories based on evaluation of their technical qualifications and competence to carry out specific calibrations or tests.

NVLAP provides an unbiased third-party evaluation and recognition of performance. Accreditation signifies that a laboratory has demonstrated compliance with NVLAP management and technical requirements, including quality systems, personnel, accommodation and environment, test and calibration methods, equipment, measurement tractability, sampling, handling of test and calibration items, and test and calibration reports. Learn more here.